Electrochemical H2 processing

Make-up hydrogen for mild hydro-treater reactions (mild-HDT) at refineries normally is fossil resource based (steam-methane reforming), brought to reactor pressures using unreliable mechanical compressors and hydro-treater reactor exhaust containing precious H2 (up to 70%) is fueling burners providing only process heat.

BioMates develops at CERTH an integrated renewable make-up H2 infrastructure consisting of:

- Solar-powered water electrolyser to produce clean hydrogen

- Electrochemical hydrogen compressor (HyET Hydrogen) for pre-storage to feed mild-HDT reactor

- Electrochemical hydrogen purifier to recycle precious hydrogen from the reactor exhaust.

These innovations can reduce the carbon footprint of the hydrogen production chain directly and via energy consumption reduction towards even self sufficient operation.

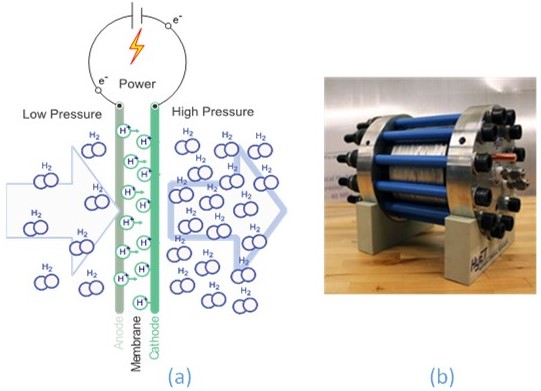

a) Schematic of working principle of electrochemical compression and purification

b) H2 compressor/purifier stack without any moving parts

| This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 727463 |